Bespoke Plinths & Display Cases

Once we know the dimensions of the base of your model, we can design and make a plinth to suit its destination and the installation. To protect your model, we make display cases of any size or shape – usually from clear acrylic. We can make a variety of shapes, working in line with the size of the model. A circular plinth offers an alternative to traditional rectangle – and means people can gather in a natural circle to view your display. Your project manager will discuss your requirements, to understand the factors which will influence how we design and build it.

Finish

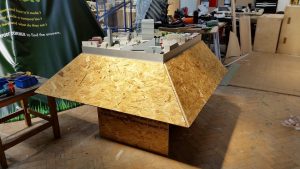

A bespoke plinth can be built in ply-board or OSB which are easy to machine, and then finished in a variety of materials or wooden veneer. For an exhibition, trade show or museum, we can design and apply graphics, so the plinth forms an eye-catching and useful extension of the model.

For display purposes, we assemble cases with a unique glue, which absorbs into joins, creating a flawless, continuous surface. Acrylic is far lighter than glass, yet we can create the illusion of a crystal clear finish. We can etch the surface of the display case to extend the boundary of a model, tracing the outline of surrounding features in the buildings or landscape, when they are important to the visual aspect of the development.

Storage space

Where required, a plinth can house the electronics, enabling us to design and include a dynamic lighting system in your model. Or we can design useful storage space in your bespoke plinth, for example, to display brochures or literature with the model.

Transportation

We select lightweight materials, which are easy to transport by road, air or rail. It is possible to design a bespoke plinth, which doubles up as a flight case, if being transported overseas. We can make a flexible wrap and fix it with hidden fittings, so installers can collapse the plinth easily, to move or re-locate the model whenever needed.

If your model is being built to withstand temperature fluctuations, we use durable materials and a heat resistant finish for the plinth and display case.

The final result in our Museum of Prehistory has been greeted enthusiastically by academics, general visitors and children, and after 4 years in operation, having seen about 1 million visitors [was] showing very little sign of wear and tear, which is a tribute to Amalgam’s exacting standards of ‘fit and finish’ and their eye for using the right materials.

Hugh Cornwall – Cheddar Caves & Gorge