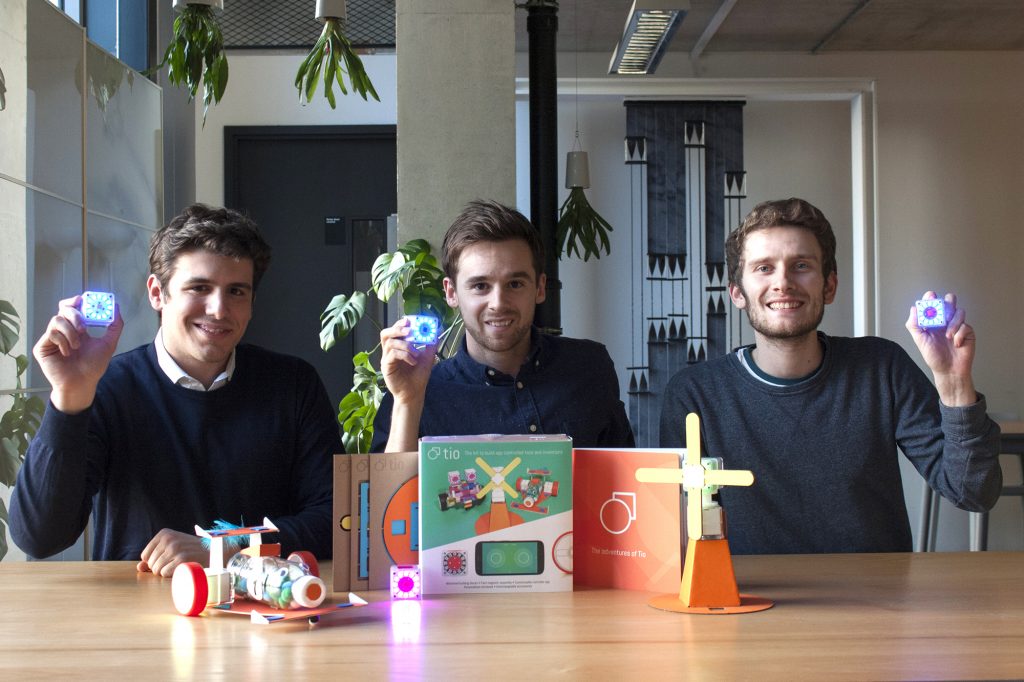

Tio, developed using our prototyping service, was dreamt up by three aspiring innovators with a vision to inspire tomorrow’s inventors. They are dedicated to creating a new way of inventing, playing and learning.

Tio is the kit anyone can use to create app-controlled toys and inventions with everyday objects and materials like recycled and craft materials, old toys, Lego, gadgets and even 3D prints. It is designed to spark invention, encourage creative play and provide a new way to acquire future skills and knowledge including creative thinking, team work, problem solving, arts and crafts, technology, design and engineering principles. The Tio Kit includes motorised building blocks with built-in LEDs, magnetic mounts, colourful wheels, interchangeable accessories, sticky tabs, stickers and a personalised storybook. It comes with nine pop and fold invention templates to get started before exploring different materials.

The free iOS/Android app communicates wirelessly with your creations to customise and program them. It controls many features like motor speed and direction as well as LED colours, rotation and patterns. With simple taps on the app, the programming mode allows creators to record and play back live actions including colour patterns and movements. Coding is possible but not required making the app accessible to all.

Using the kit, adults and children with no technical expertise, can create an infinite number of toys and animate the world around them. You can now get the Tio Kit on Kickstarter.

Tio’s requirements of our prototyping services were:

– To achieve high tolerance parts, allowing for moving components and magnets.

– To accommodate electronics and lighting, adding to the visual appeal.

– To apply a soft ‘tyre’ over the wheel detailing.

– To have a crisp finish and be bright in colour.

– To be robust enough to survive the impact of trial playing and regular usage.

Amalgam produced 3D printed components to test the digital design for the Tio parts, using VeroClear resin. This material has properties similar to acrylic and is transparent, to clearly see the internal details of the parts. This step in the prototyping process aided Peter, the co-founder and inventor, to develop the design further.

The next phase was to produce casing units for fully working prototypes of the Tio units. The challenge was to create eight units for demonstration purposes – and these needed to be attractive enough to enter competitions and underpin the Kickstarter campaign for Tio.

New 3D prints were prepared as vacuum casting masters for the components with a specified desired finish. This means the parts required hand-finishing to achieve a high gloss finish for all clear components, and a smooth satin finish for the coloured components. Parts were checked for fit, and then we invited Tio back in to double-check them and discuss development. Once these components were ready, we went ahead with the tooling.

To ensure we produced these components as efficiently as possible, we created multi-cavity moulds from which we vacuum cast multiple parts of similar size and material. Our process always protects the critical dimensions and fine detailing. Once the silicon moulds were complete, we began the casting process. For the Tio components, we selected an optically clear, high impact polyurethane resin formulated to closely mimic ABS. We had Pantone references for a few of the favoured bright colours for the Tio prototypes, which we colour matched as a part of the casting process.

For this project, our prototyping service included fitting the magnets and constructing the eight fully working cases, ready for the electronics to be fitted. In the assembly phase, Peter spent a day with us, assisting with bringing the parts together, and fitting printed circuit boards and motors. The components were fettled and adjusted for fit to meet the critical dimensions of the design. Working this closely with the client allowed us to make sure we produced exactly what he required to bring the Tio kit to life.

We are very happy with the quality of Amalgam’s work and their speed of delivery. We’ve been running many workshops with children, parents and teachers and are delighted to say the prototypes have delivered on every front, in particular enabling us to bring the product and our mission to life. Since the delivery of the prototypes, we have been able to create appealing visual assets to use with traditional and social media and successfully launch our Kickstarter campaign.

Peter Spence, Tio co-founder and inventor