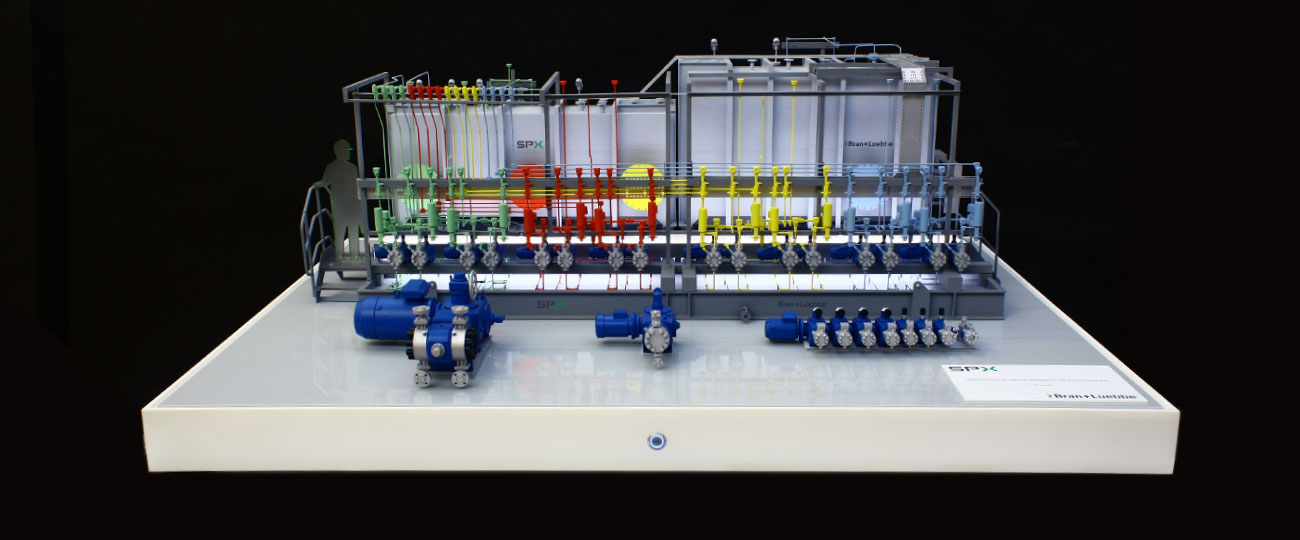

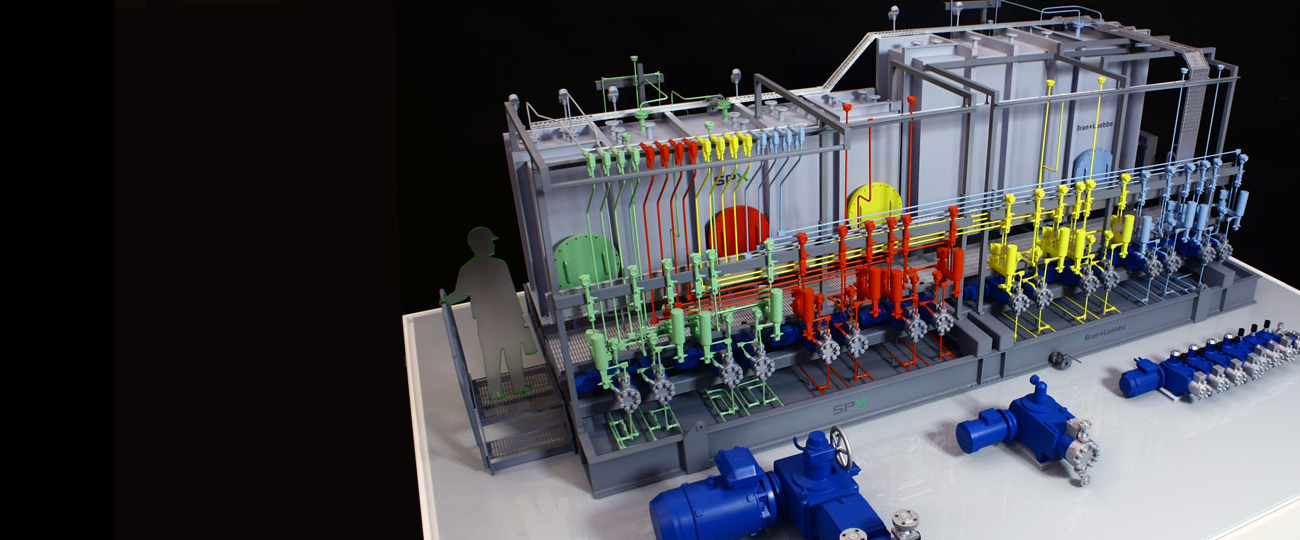

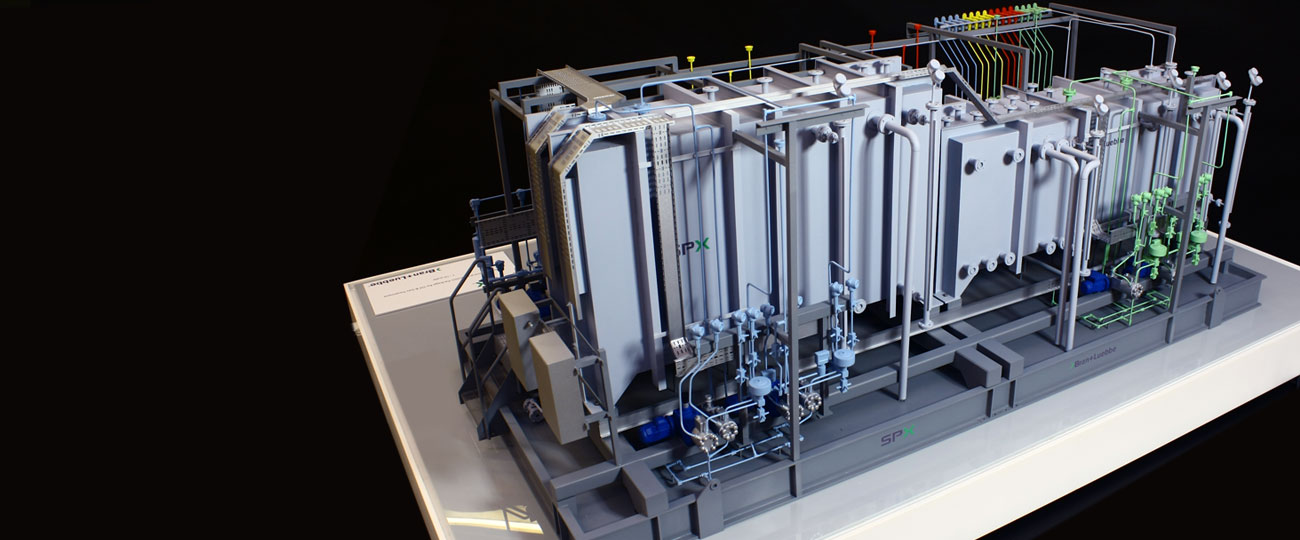

This 1:10th scale Large Chemical Injection Package Model for SPX was built to be displayed at various international oil and gas trade shows and conferences. The level of detail goes right down to rivets and bolts, adding up to a busy, populated, high-detail model with plenty of interest.

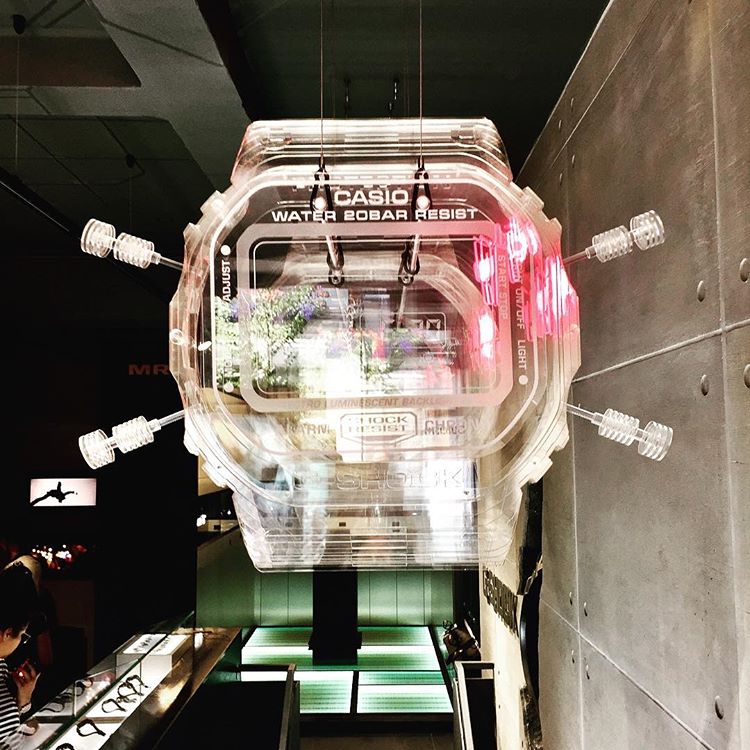

As a point of interactivity, we added an illuminated walkway, activated by a button on the baseboard. Lighting within models can be used subtly, as with this model, or dramatically, as in some of the competition models we’ve made over the years.

Our vacuum casting facility enabled us to create the array of detailed pump units set around the model; these were 3D printed from digital files, finished by hand and cast in durable resin. Producing components in this manner combines the reliable tolerances of 3D printing, the quality of finish that hand skills and traditional model making provide, and the capability of vacuum casting to replicate both of these qualities in large numbers very quickly.

We also used additive manufacturing processes to make ‘kits’ of parts that could easily snap together. Making the fittings this way enabled us to keep the pipework and pumps fixed at right angles and straight lines, and lock together into rigid modular structures that could be assembled easily.

Other structural engineering models for the oil and gas industry we have made along similar lines include the Chickmaster CC3 unit and the Asry-Centrax Powerbarge, both high-detail structural engineering models.