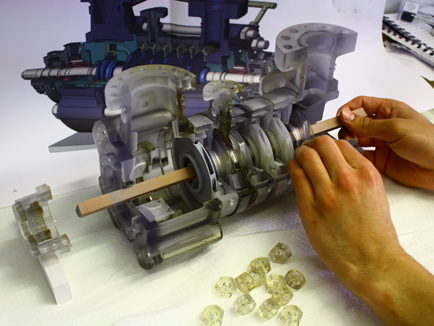

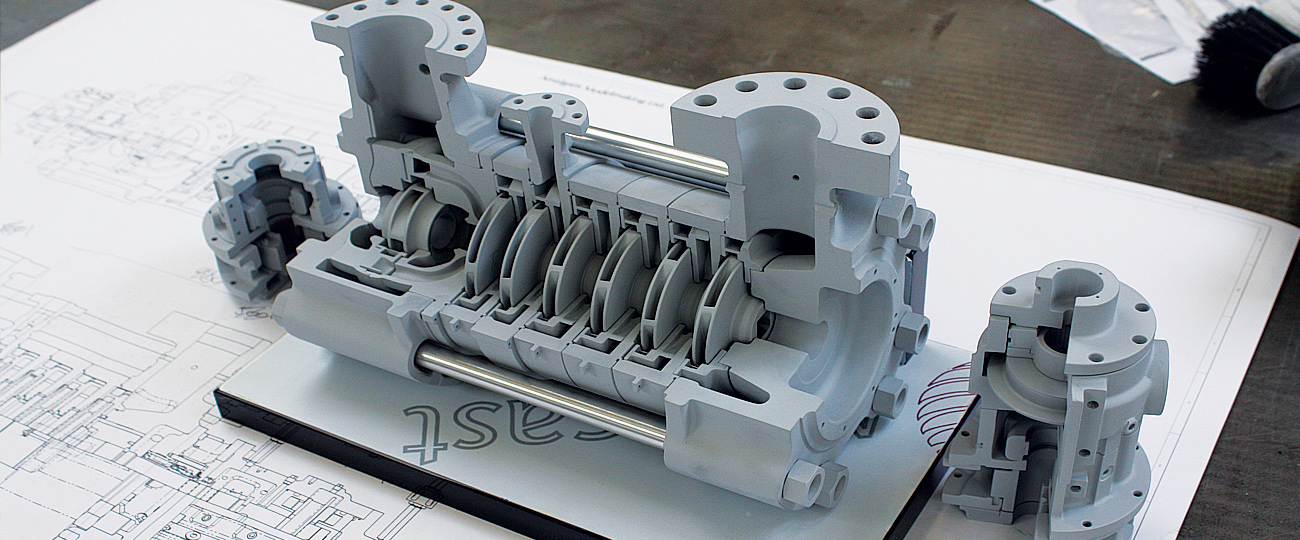

This section model was created almost exclusively with 3D printing processes, each component being meticulously hand-finished to fit snugly back together. Having received the client’s design, our technicians extensively processed the technical CAD into 3D print ready files. Each face, curve, ridge and internal radius was carefully sanded and top-coated to achieve a high-quality graphic finish.

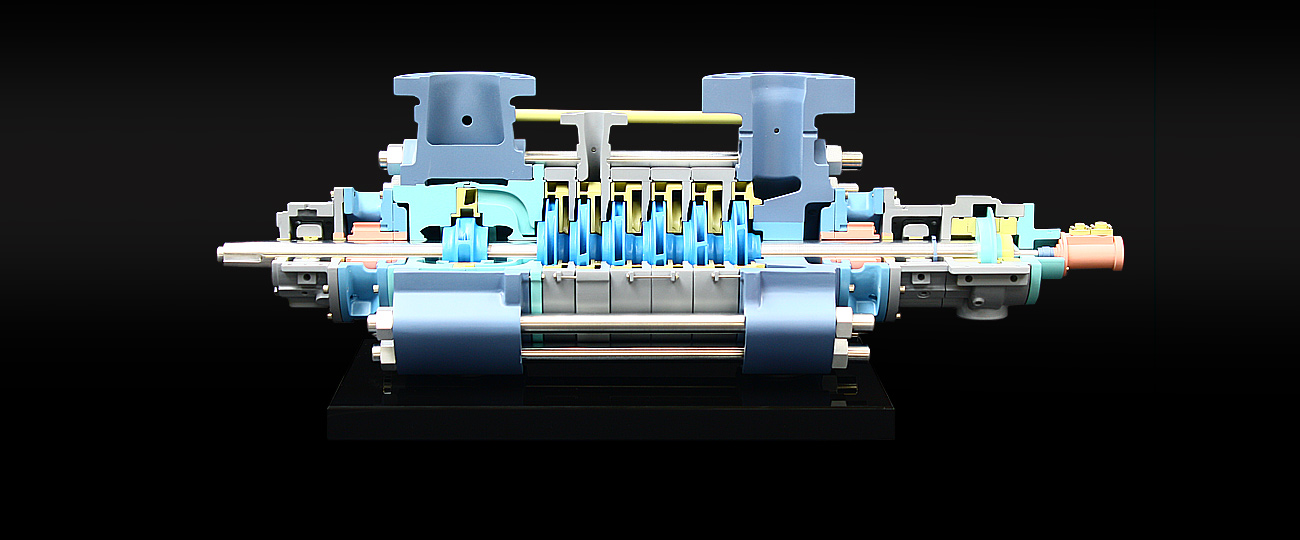

The colours are intended to highlight the different functional components of the unit, matched to the client’s specification. To complete the high-end display model, the whole assembly is mounted on a crisp gloss black presentation baseboard.

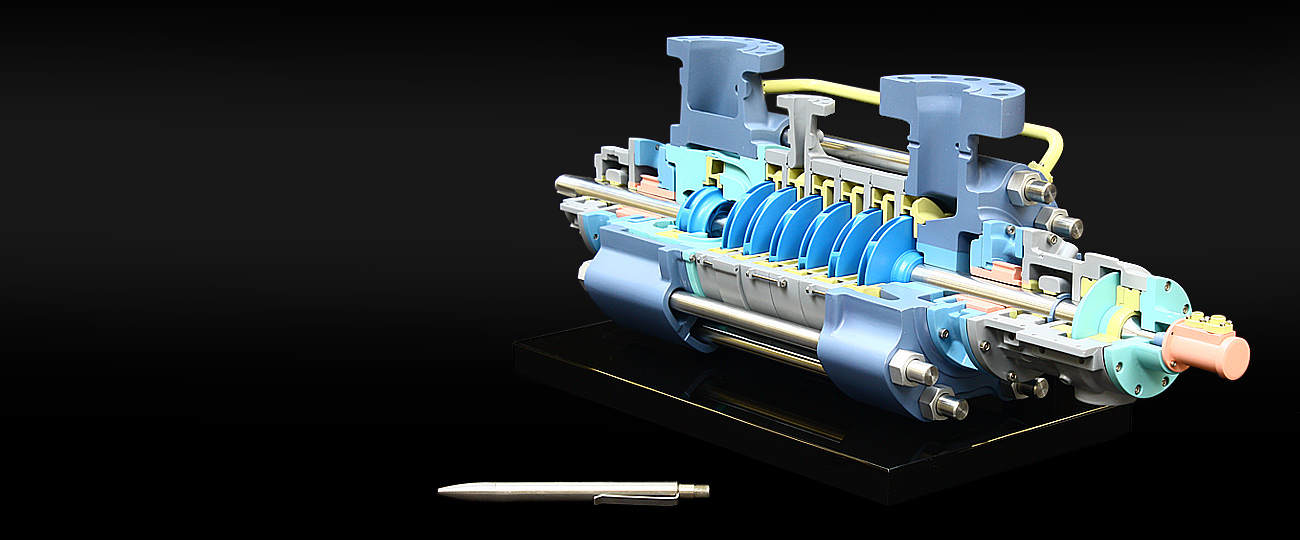

Display models presented in this manner are incredibly useful sales and promotion tools. While this model is a detailed bolt-for-bolt replica of a production unit, it is presented as a highly graphic, illustrative section model – almost a technical drawing in three dimensions.

The advantage this manner of presentation has over screen displays or static images, particularly in the context of trade shows and exhibitions, is to engage the audience. Physical section models are an extremely efficient means to communicate unique selling points and design features. A viewer is able to see the principles at work under the hood, and can appreciate the time, craft and engineering that has gone into developing a product for its purpose. This creates an understanding of the advantages the product has to offer on a much deeper level than written or verbal information.

Other projects in a similar category that have been particularly successful include the Chickmaster CC3 Temperature Regulation Unit, and the range of models we have provided for SPX Flow Technology including the Continuous Processing System and the CEP cutaway model.