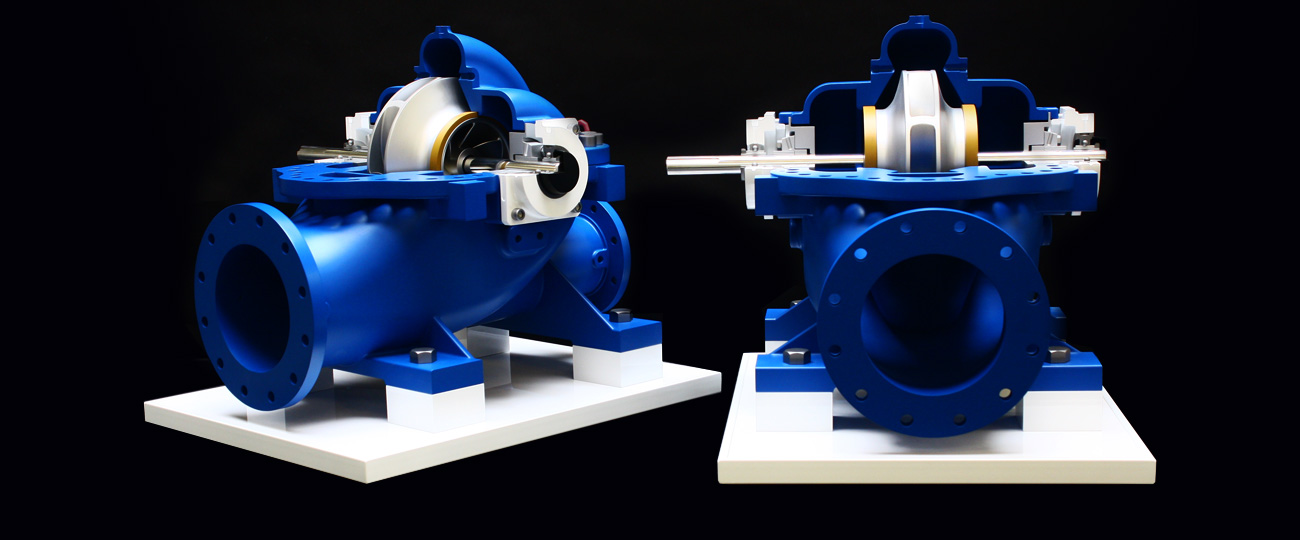

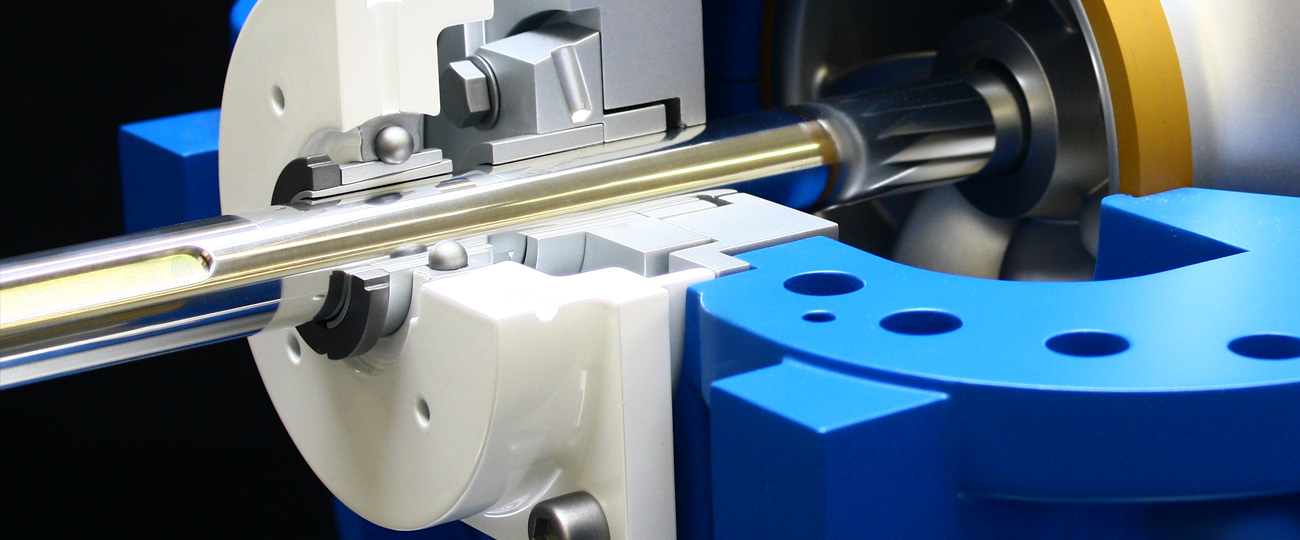

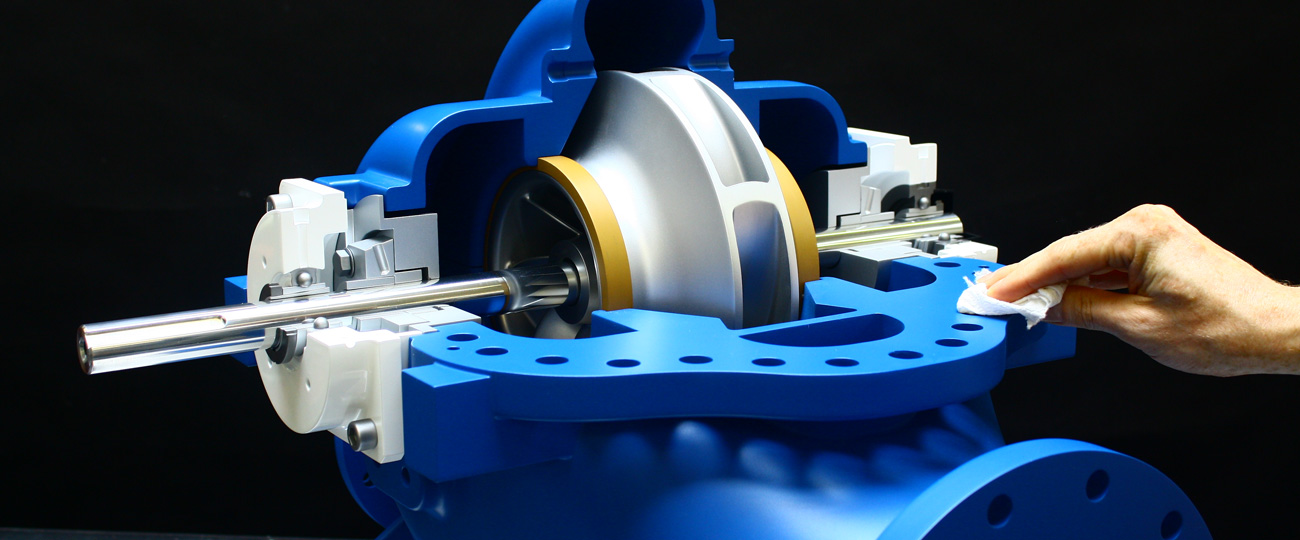

We made these two huge models for SPX Flow Technology using a form of 3D printing to give us our fundamental shapes and tolerances, having taken 3D CAD directly from the client and processing the drawings in-house to be ready for printing. As with the other models we have made for SPX Flow Technology – the CEP Section Model, FT Section Model and Continuous Processing Models – the 3D printed parts were meticulously hand-finished to bring the surfaces up to a sharp graphic finish, and preserve the tolerances of the interconnecting parts.

This method of manufacture allowed us to engineer a good amount of durability into the construction, since the models would be travelling to various international trade shows.