Technical 3D design for a high impact display

When a new product is ready for the big reveal, a large scale in-store display often works to grab attention and get people talking, which we talked about for premium brands. To create a high impact display, it’s often the technical detail which matters most – looking at how the display is made, and what structural support or suspension points it needs – to be congruent with the design.

The process starts with our clients’ ideas; when they come and talk to us, our role is to interpret their design and bring it to life. We always aim to achieve a result which looks sleek, with no interruptions on the aesthetics of the finished display. Making something appear that way can take time testing and iterating the physical features in 3D CAD.

Where to use a large-scale creative display?

The obvious answer as to why choose a large-scale model is to stop people in busy places when they otherwise will be walking by, not stopping unless something catches their eye. In our experience, it is possible to take any product, re-draw it or adapt the existing CAD and scale the design to produce at a larger size. We’ve done this for very small medical products, consumer goods and industrial machines. Locations where our large-scale models work well include:

- Flagship retail stores – celebrating a product on its launch or an anniversary year

- Trade shows – to share a new or adapted design on the manufacturer’s exhibition stand

- Museums – to aid education by showing more of the specific detail

- Film-shoots for advertising – to capture special effects inside a replica product

Factors to consider for large-scale models

Displays are frequently designed and produced in a workshop like ours, then transported and installed on site. We make display and exhibition models which travel all over the world; some are kept in storage then moved when needed for an exhibition, others are installed in a fixed location, or a temporary pop-up retail store.

The key factors to consider when constructing the model are:

- Durability

- Weight

- Environmental or weather conditions

- Assembly

Depending on the form or design, we select materials from a wide range, choosing which process will achieve the desired effect for the display. Creative artworking enables us to deliver a convincing finish on the final piece – applying special effects, textures, or specialist paints. For the suspended display in the case study we used acrylic, which can be machined, laser-cut and etched or engraved for a sharp finish.

Creating a large-scale centrepiece display for G-Shock’s Carnaby Street Store

When we helped Double Retail deliver the final piece for their grand opening of the Carnaby Street Casio store in London, our brief was to expose the layers of the G-Shock watch in an outsize model. Amalgam Project Manager, Glen, worked with project lead, Dave Corke from Double, adapting the design drawings to bring the idea to life.

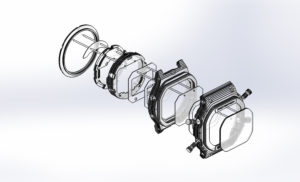

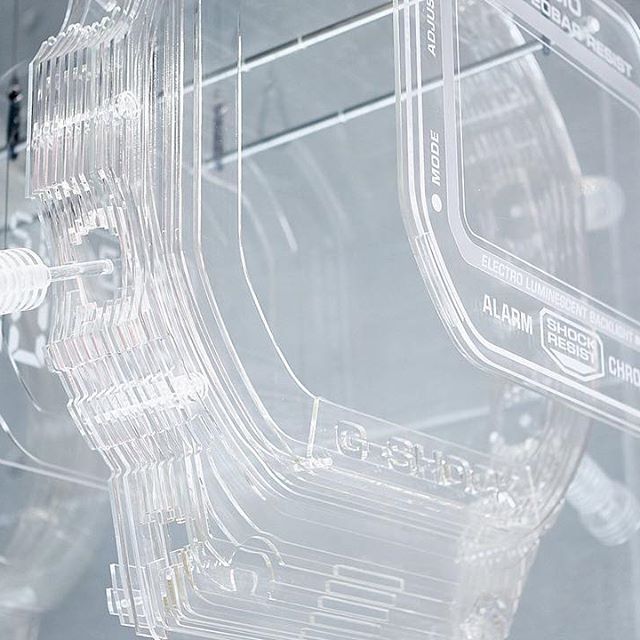

The first step was to re-create the layers of the G-Shock watch design in 3D CAD. Clear acrylic was an obvious choice to give the piece the required transparent, line-drawn feel. We opted to use laser-cutting for its crispness and economy, although CNC machining was also considered as a method for producing the display.

One key challenge was how to suspend the exploded watch above the store counter without interrupting the design. We developed renders showing options for holding each layer in place; deciding on fine steel rods with spacers and plates to make it easier to install.

Our last tasks were to check the assembly and provide a guide for the installation team on where to attach each of the points, then ship the final piece to London.

The design was realised with a sharp, clear finish creating an eye-catching and technical looking display of the exploded watch, highlighted by the pink neons. The overall in-store experience by Double Retail reflects Casio’s longstanding reputation for high-quality engineering and the G-Shock brand.