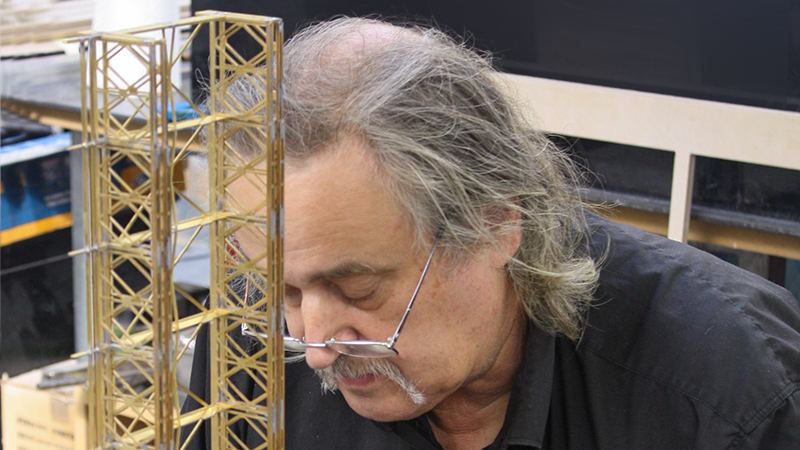

Meet Mike Quarry, one of Amalgam’s engineers working on all sorts of projects. He’s been…

An overview of our CNC machining services

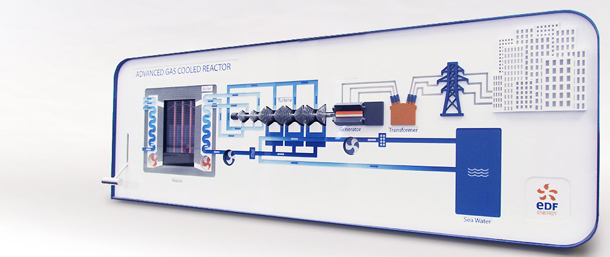

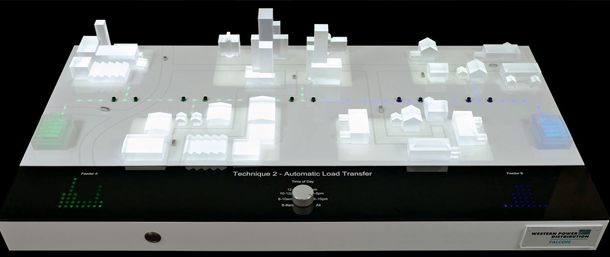

At Amalgam we provide a range of premier CNC machining services. This covers machining forms from client-supplied CAD, to being able to offer a complete end-to-end design and fabrication service. We can develop technical drawings based on conceptual images, machine the parts and assemble the structure, all completely in-house. We can also arrange for transportation and installation of larger projects, as we did with the range of EDF Energy interactives.

Beyond simply being a cutting tool for sheet material, we are constantly developing new and better techniques for using the CNC within our workshop. In this article we’ll be going over some of these applications, which in turn are services we can offer our clients.

Substructure Design and Fabrication

This Rooftop Yurt was one of three constructed for the Timber Frame Company as an interlocking skeleton of ribs cut from sheets of plywood. The structure was then skinned with timber and copper creating a sealed environment. By far one of the largest pieces of structural engineering we’ve undertaken, the Yurt demonstrates how a large rigid form can be made relatively simply. Our involvement in this project was truly end-to-end; we scanned in the original models, used these drawings to develop our CAD and machined out all of the parts ready for assembly.

‘Amalgam were able to take care of the whole process, from developing the drawings to cutting the parts. We were extremely pleased with the result.’ – Will Bateman, The Timber Frame Company

3D Contoured Forms

We have used our machine’s capacity for cutting compound-curved surfaces to create landscapes, boats and other fine-tolerance forms that would take far longer by hand. We cover a range of ground with the marine models we make, from heavy industrial craft to luxury superyachts and sailing craft. CNC machining allows us to carve out the hulls and superstructures with digital precision, to be assembled and finished by hand. The Dubois 58m Sloop and the BMT Defence Services LSV are two models we’ve made recently which demonstrate the range of styles we can provide.

Aluminium and Metalwork

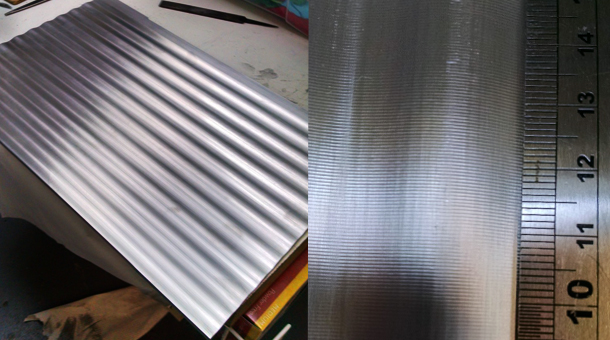

One of the more striking projects we’ve undertaken is a set of machined aluminium panels, machined with a continuous undulating surface before being powdercoated.

We were conscious of how prone aluminium is to toolmarks, and appropriately configured our machine to produce a consistent surface finish by setting a balance of cutting direction and speed.

While deceptively simple, this set of momentary switches with numeric values engraved into their stainless steel surfaces involved careful setup. Since the central button of the switch was free-moving within the assembly of the switch, we had to develop a jig which would clamp the button firmly in place, but also allow the chuck of the CNC enough room to reach the button face. Our solution was to embed the switch into a thick sheet of plywood, and clamp over it a turned aluminium ring; the whole arrangement held the button still while allowing the cutting head space to work.

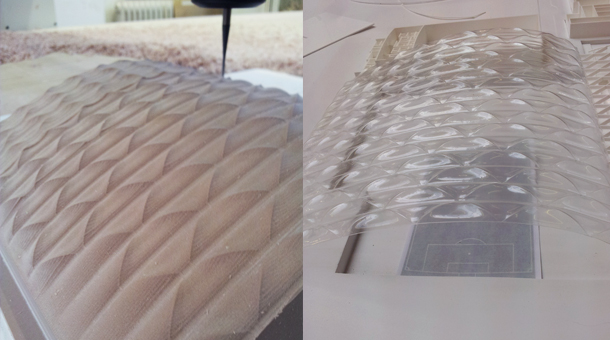

Vacuum Forms

We also make good use of 3D CNC machining to produce master patterns for vacuum forming. This is particularly useful in providing complex organic shapes such as canopies, brise soleil and elevations for architectural models, formers for blister packs and much more besides. The master form can be machined out directly from the 3D technical drawings supplied to us, from a solid block material, over which we can heat form various clear & opaque sheet materials, creating our final form.

We are still pushing the limits of what we can achieve with CNC machining technology; by a combination of continuous experimentation and a willingness to take on new challenges, we have accrued a wealth of knowledge and our experience allows us to offer our clients a premier CNC machining service.

To discuss your project with us, simply get in touch, or have a look at the following models that have made good use of our machine.