Meet Mike Quarry, one of Amalgam’s engineers working on all sorts of projects. He’s been…

Process flow models – to realise a 3D proof of concept

Some clients come to us for a model, when making engineering changes, or re-designing a process flow. These businesses may be working in manufacturing, or energy sectors, where the changes need to be shared with stakeholders around the company, and across the industry.

So, today we take a look at the top reasons why a 3D model helps, when explaining a complex or technical process flow.

Top reasons for creating a process flow model

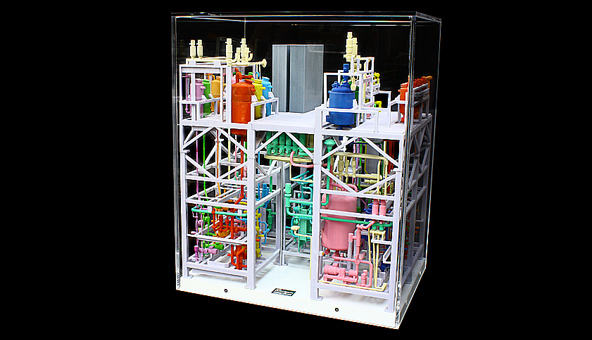

1. When a concept is highly technical, a model enables you to simplify it – and use dynamic lighting or coloured parts to mark specific aspects.

The SPX Flow Continuous Processing Industrial Display model (shown above) is a great example of how we apply our CAD skills to develop a design ready for 3D-printing a huge number of component parts. Once the parts were finished, they simply clicked together to create the eye-catching industrial display, showing the process flow of recycling waste within a production facility.

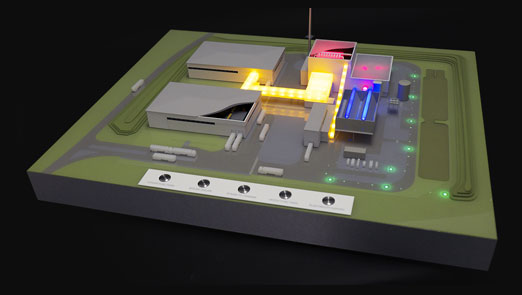

2. Turning a process into a 3D model allows the audience to visualise it; so when you are re-designing a process, a model allows you to make the changes very tangible.

For Western Power Distribution, we developed a series of models using LED lighting. Each model in the range illustrates a different aspect of electrical power management in a low-carbon network. Part of the work to design these involved turning the principles of the process into a physical object, to effectively communicate the relevant information.

3. An eye-catching, full colour model helps engage the attention of senior executives or investors, when you need their buy-in to understand a process.

This Solar Energy House was built for EDF to explain the micro-generation process for solar energy. Building a full colour detail version led to the creation of more portable versions for EDF to use around the country.

4. Standing around a physical model allows you to point, indicate and highlight the relevant sections of the process or technical concept being addressed. If you make the model interactive, the user can test the process for themselves.

We built an interactive model showing a renewable energy plant, where participants can engage in the process flow, using the row of buttons on the front panel. The lighting on the model shows the separate stages of the biomass energy generation process. Activating the stages in the correct order results in the audience seeing the energy being generated and fed out to the grid on the display.

Many of our customers have found that by creating a 3D model of a process flow means making their case for improvements has become much easier. As we’ve said before, a picture may paint a thousand words, however, a model saves thousands more.

Talk to us about your engineering or manufacturing challenges – to explore how a physical model will help.