Royal Artillery Monument

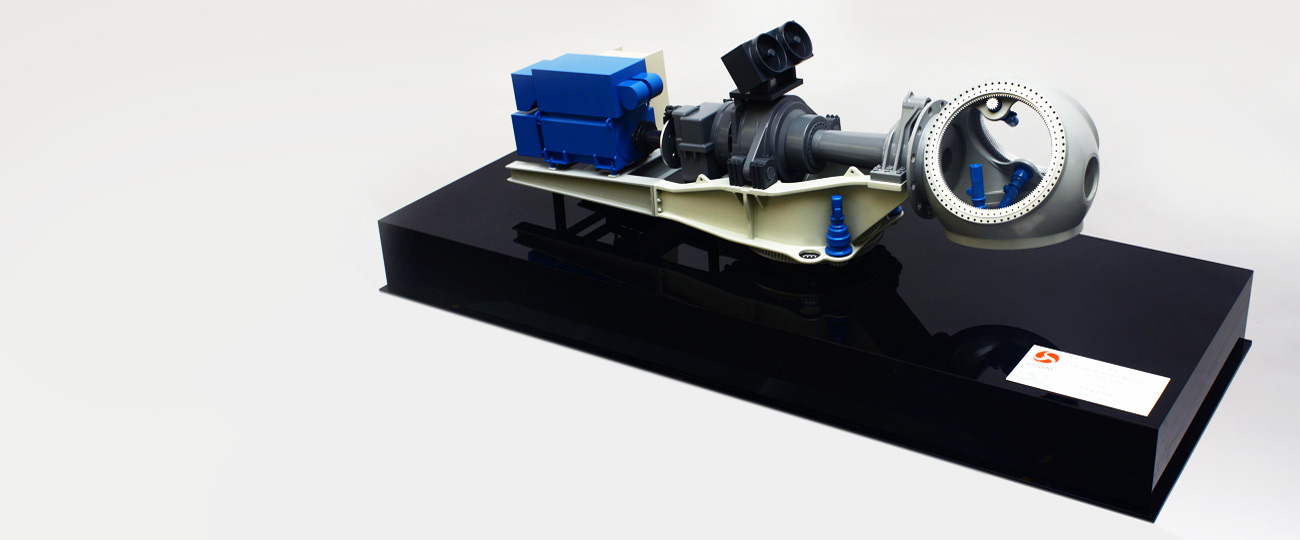

This imposing military model was made for Peter Hicks Ltd. to be used as a centerpiece for official events held by the Royal Artillery. The intricate relief carvings were sculpted by hand, then cast in a specialist material that provided a realistic base for artworking into the texture and colour of Portland stone. The detailed fontwork and text was delicately carved out with our CNC machine to ensure precision. We have made a range of military models over the years; however, these have usually been cutting edge pieces of prototype hardware, such as the BMT Mastif. With the Royal Artillery Monument we had to replicate the intricate stone sculpture and relief work around the base.